Molded pallets hot press is a new type of plant fiber molded pallet production equipment, which uses hot melt adhesive hot pressing technology for one-time molding. The hot press machine for molded plant fiber pallets meets environmental requirements and can recycle raw materials such as wood chips, waste wood pallets, waste wood, wood, kraft paper, straw, bamboo, etc. to make molded pallets.

First, plant fiber molding tray overview

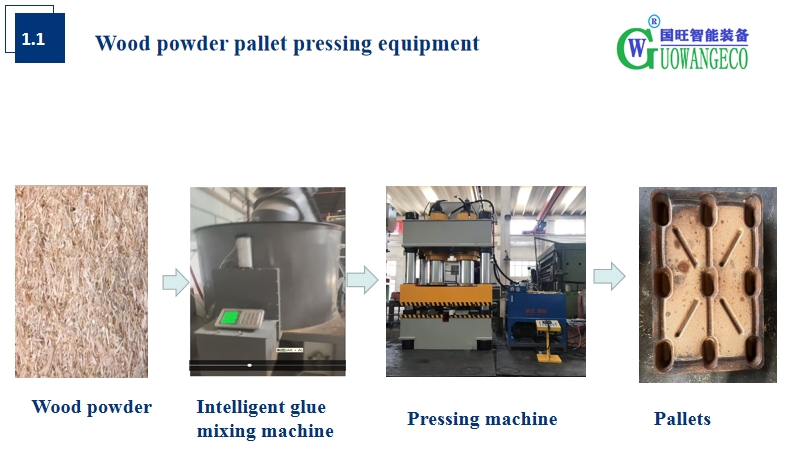

GW ECO-TECH pallet hot pressing line is a new type of plant fiber pallet pressing production equipment, the equipment adopts hot melt adhesive hot pressing process one molding. Moulded plant fiber tray Hot press in line with environmental requirements, can be recycled raw materials such as wood chips, waste wood pallets, waste wood, wood, kraft paper, straw, bamboo, etc made into moulded pallets.

Second, plant fiber pallet materials: waste wood, waste wood chips, sawdust sawdust, shavings, wood chips, large wood chips, logs, burned forest, logs, boards, branches, wood, wood chips and waste pallets, which contain rich fiber fibers can also be used to produce pallets, such as straw, waste kraft paper, bamboo, palm, coconut, cork, wheatgrass, bagasse and platycodon.

Three, plant fiber molding tray hot press

The equipment adopts four-column structure, high positioning accuracy, and the pressed products do not deform

PLC control system, one key operation pressing and taking out molding, high efficiency, high output, equipment can be configured with automatic feeding and taking out palletizing device

Four, the characteristics of plant fiber molding tray

1, low moisture content, constant strength and stiffness.

2, the board does not absorb moisture, in the use of the process will not be deformed.

3, stable size, no deformation and warping.

4, high precision, light weight.

5, it is specially designed reinforcement, can ensure strength and production accuracy.

6, fumigation-free, widely popular in import and export transportation.

waste wood, wood chips, sawdust, shavings, wood chips, large sawdust, logs, burned forests, logs, wooden boards, branches, wood, wood chips, and waste trays. Fiber rich in fiber can also be used to produce trays, such as straw, waste kraft paper, bamboo, palm trees, coconuts, cork, wheat straw, bagasse, and platycodon.

The equipment adopts a four column structure with high positioning accuracy, and the pressed products do not deform

PLC control system, one click operation for pressing, removing, and shaping, with high efficiency and high output. The equipment can be equipped with fully automatic feeding and removal stacking devices.

Low moisture content, constant strength and stiffness.

Wooden boards do not absorb moisture and will not deform during use.

Stable in size, without deformation or warping.

High precision and light weight.

It is a specially designed reinforcing rib that ensures strength and production accuracy.

Free from fumigation, widely popular in import and export transportation.

Wood (plant fiber) → Chipping → Crushing → Drying → Mixing glue → Hydraulic press hot pressing → Pallet finished products.

Get Plastic Recycling Machine from Guowang Eco for Different Applications.