Waste plastic houses are an example of waste plastic utilization that has emerged in recent years. Waste plastics are everywhere on earth, but the utilization rate is very low, especially the utilization of mixed waste plastics is even lower. In order to solve this problem, Anhui Guowang Environmental Protection Technology Co., Ltd. has invested a lot of manpower and material resources in recent years to devote itself to the research and development of waste plastic utilization equipment, and has achieved promising results. Has developed a “mixed waste plastics one-step tray extrusion molding equipment” is mainly the use of film type of mixed waste plastics. The “two-step tray extrusion molding equipment for mixed waste plastics” mainly utilizes rigid mixed waste plastics. The “Waste Plastic House Brick Production Equipment” focuses on solving the problem of applying mixed waste plastics in house construction.

There are many types of waste plastics, which can be summarized into the following two types.

Film-type mixed waste plastics:

1.Domestic waste plastics:

2. Paper mill garbage and plastic waste

3. Plastic film and greenhouse film

4. Packaging waste plastics

5. Tetra Pak, food packaging film

6. Other industrial films, etc

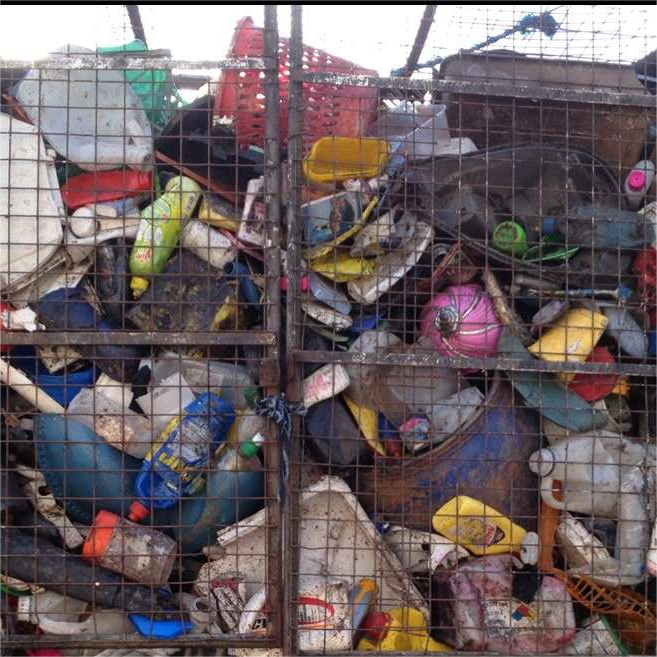

Hard waste plastics:

1.Iron plant waste plastic and miscellaneous materials

2. Industrial machine head materials and miscellaneous materials

3. Household appliance waste plastics

4. Daily necessities

5. Materials, pots, baskets, toys, etc. used in daily life; Various types of barrels, bottles, etc; Other hard materials.

6. Fine grained materials or crushed materials made from thin films or hard materials

In short, no matter how mixed the above types of waste plastics are, whether they are thin film materials or hard materials, as long as they are clean and free of impurities (such as iron, stainless steel, stones, etc.), they can be used to produce the various types of waste plastic bricks we need using the "waste plastic house brick production equipment", and build various types of houses and other buildings. Houses made of waste plastic are insulated, energy-saving, and environmentally friendly. The use of waste plastic can reduce environmental pollution and benefit future generations.

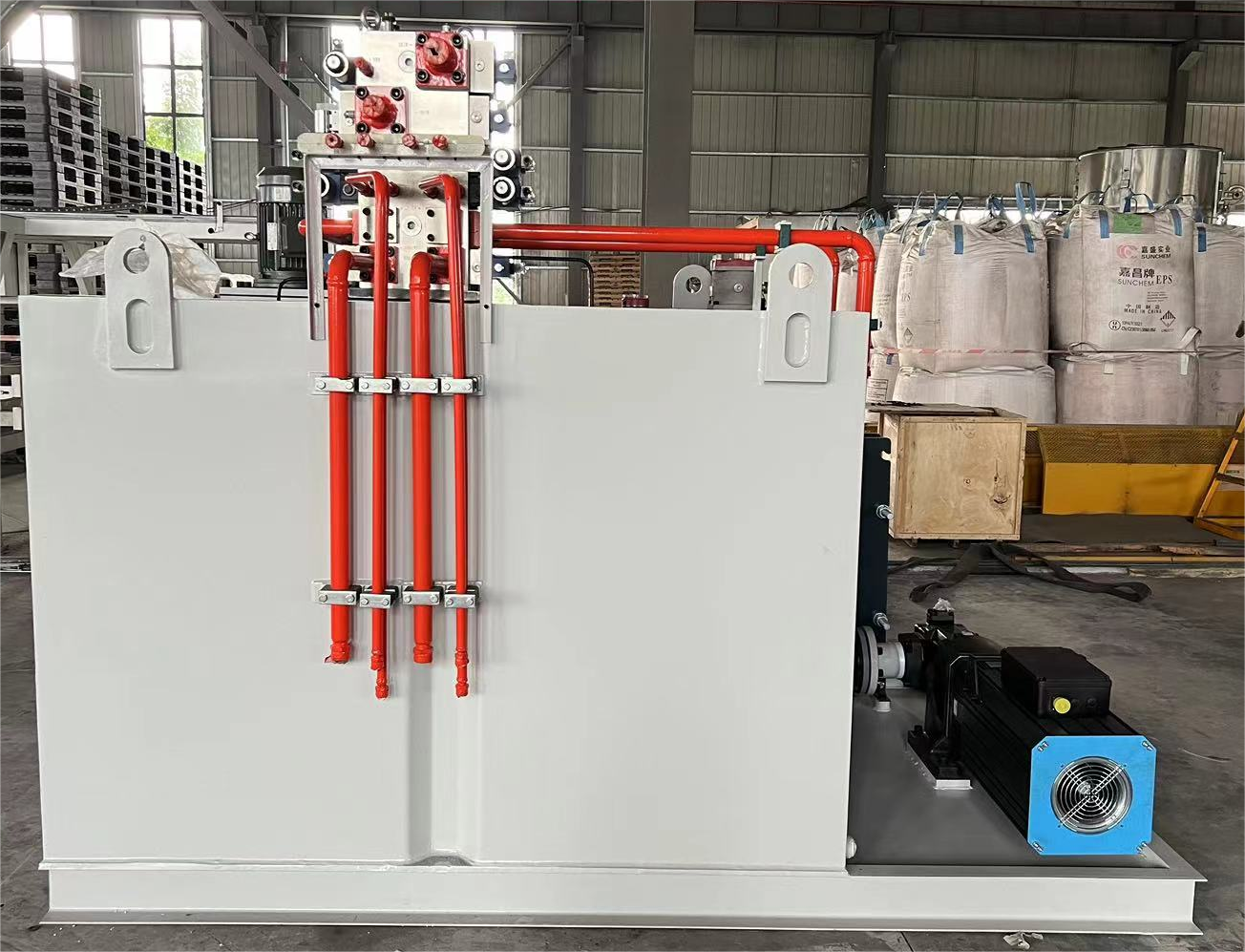

1、 GWRRSJ500L plastic melting and plasticizing machine (2 units)

Melting plasticizer is a specialized equipment developed by Anhui Guowang Environmental Protection Technology Co., Ltd. for building bricks. The biggest feature of this equipment is that no matter how mixed the waste plastics are, whether they are thin film materials or hard materials, they can be added to the equipment for processing

Mixing and plasticization are the ways in which plastics can achieve the goal of producing plastic bricks.

2、 GWDLG-1 single screw waste plastic brick extrusion equipment

A single screw extruder extrudes melted and plasticized plastic into a storage tank, and injects it into a mold with a storage device to produce the desired finished product.

3、 Reversing and storage system

4、 Hydraulic system

5、 Auxiliary system

By using an auxiliary system, the products squeezed into the mold are cooled, lifted into the platform, and extruded out.

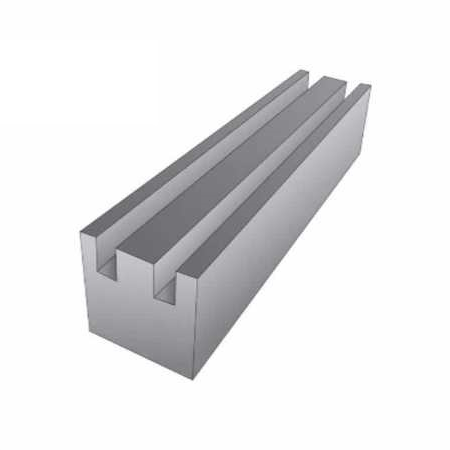

6、 Mold

1.Thread through brick one;

2.Thread through brick two;

3. Plastic bricks;

4. Plastic columns;

5. Plastic window frames;

6. Plastic bottom frame;