The amount of Stale refuse plastic waste in landfills of domestic waste sources in the world may be more than 4000 million tons, and the waste plastic in global landfills of obsolete waste is about 2.3 billion tons. Stale waste plastics if not properly treated, will have a serious impact on the environment, it is difficult to degrade in the natural environment, plastic takes decades to hundreds of years to degrade, in the degradation process may release harmful substances, posing a threat to the ecosystem and human health.

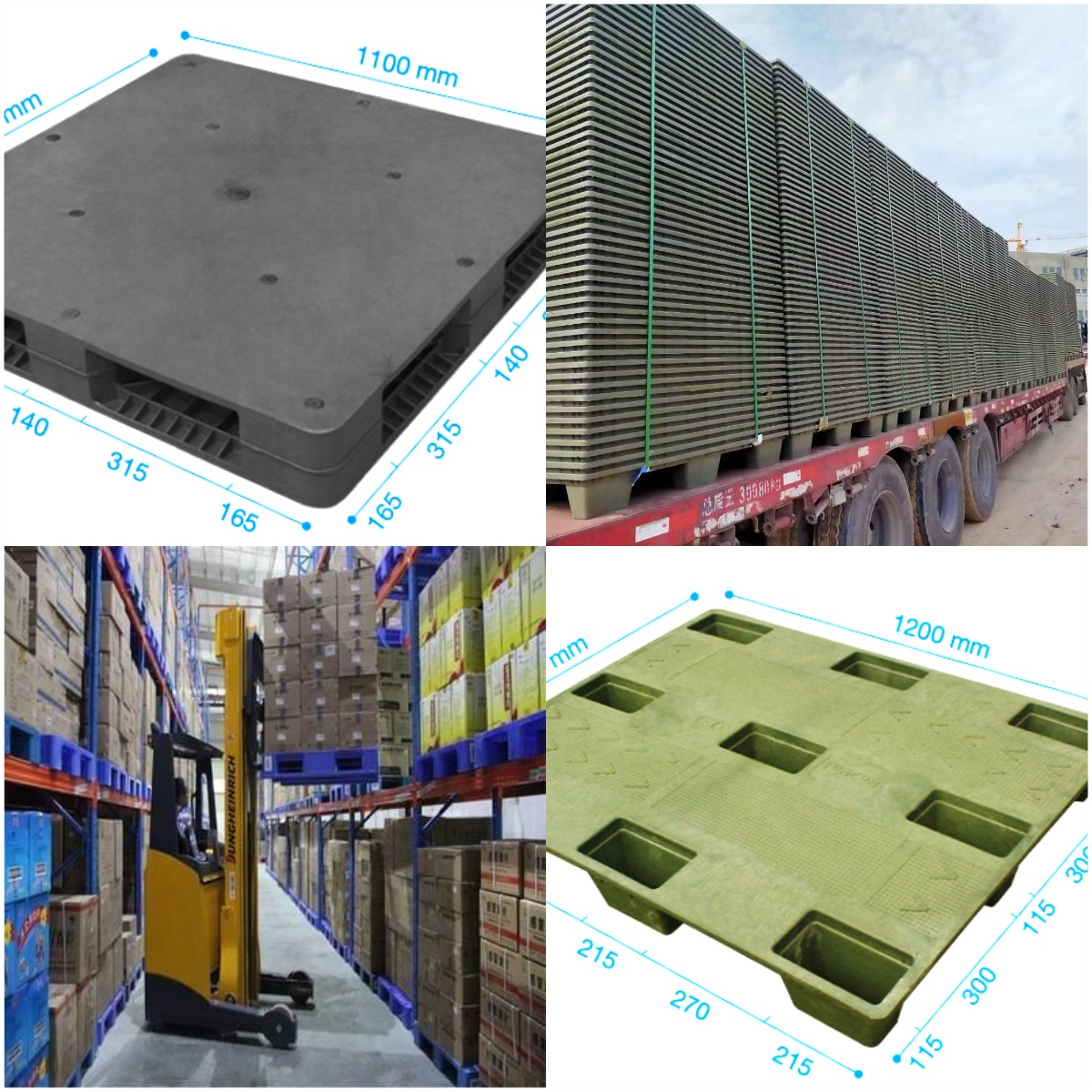

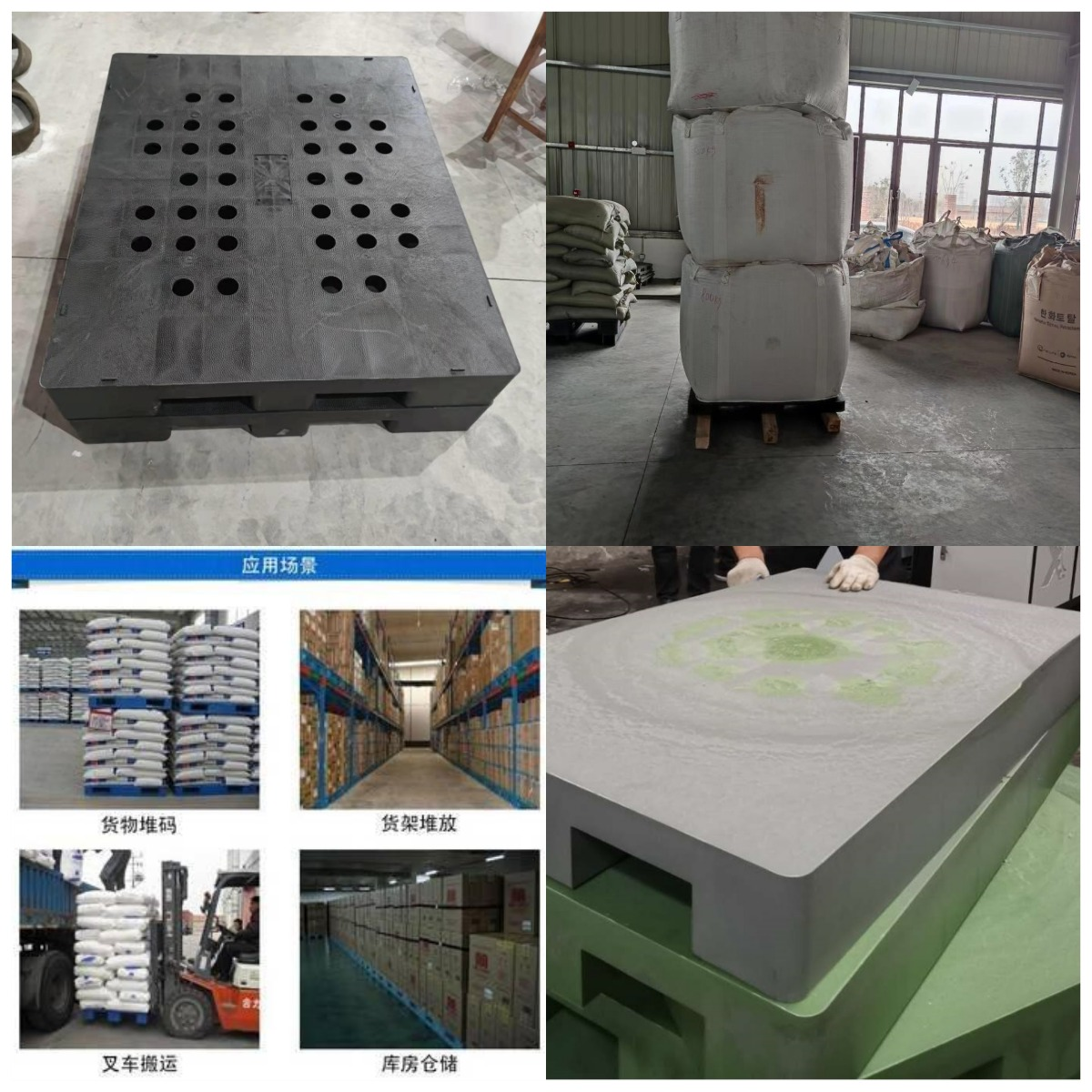

Guowang Eco-Tech research and development of landfill waste plastic pallet pressing line which can turn landfill Stale refuse waste plastic waste into treasure, making a variety of high-quality pallets.

Large stock and wide distribution of stale waste: With the widespread use of plastic products and the increase of waste generation, there are a lot of stale waste plastics in landfills. The cumulative production of plastic products in China exceeds 1.2 billion tons, of which more than 90% May eventually become garbage, the landfill plastic waste volume of domestic waste sources alone may be more than 400 million tons, and the waste plastic in the obsolete waste in the global landfill is about 2.3 billion tons. Only 16% of the plastic waste generated globally in 2016 was recycled, with a physical recovery rate of 12% and a chemical recovery rate of less than 1%.

If stale garbage plastic is not properly treated, it will have a serious impact on the environment, such as occupying land resources, polluting soil and groundwater. It is difficult to degrade in the natural environment, plastic takes tens to hundreds of years to degrade, in the degradation process may release harmful substances, posing a threat to the ecosystem and human health, so its environmental impact has received more and more attention.

In order to solve the green cycle and high value utilization of obsolete waste plastics, GW Eco-Tech has conducted a lot of research, aiming at the "complex composition of obsolete waste plastics is not easy to plasticize; The impurities are difficult to remove;" Several targeted tests were carried out to solve the problem of difficult plasticizing of stale plastics, and a special melt plasticizing machine was developed. Due to the problem that many stale plastic impurities are difficult to remove, the injection molding method is changed to solve this problem; Thus, a special equipment suitable for stale waste plastics has been developed, and good results have been received.

By replacing mold can produce a variety of different products, such as: tray, manhole cover, flower pot, square brick and so on.

Model | Frequency (pcs/min) | Pressure (T) | Output (KG/H) | Total Power (KW) | Products size | Screw diameter(mm) | Outside dimension (L*W*H) | Weight (Ton) |

GWJZD-1 | 1.5-2 | 315 | 100-150 | 45.63 | 300*300 | 90 | 6000*1460*3500 | 25 |

GWJZD-2 | 2-3 | 1500 | 350-450 | 250 | 1500*1300 | 65/130 | 10000*5400*6000 | 85 |

GWJZD-3 | 2-4 | 2000 | 400-550 | 330 | 1600*1300 | 75/180 | 12000*5800*6500 | 120 |

Hard materials include:

Clean: granulated material; iron factory material; industrial machine head material; home appliance material; pallet, etc.

Need to be cleaned: Materials used in life, baskets, toys, pots, etc.; Various barrels, bottles, etc.; Other materials.

The fully automatic two-step plastic pallet molding equipment adopts the co-rotating conical twin-screw specially designed by our company. The characteristics of the screw are smooth feeding, strong shearing force, and uniform dispersion. Due to the lengthened screw, the plasticization is good, and it is suitable for mixed waste plastics. Through precise design, it is ensured that the weight of each pallet is basically the same, and the error does not exceed 0.1 kg. The whole line is controlled by PLC and has a high degree of automation. One production line can be completed by only one person.

Get Plastic Recycling Machine from Guowang Eco for Different Applications.